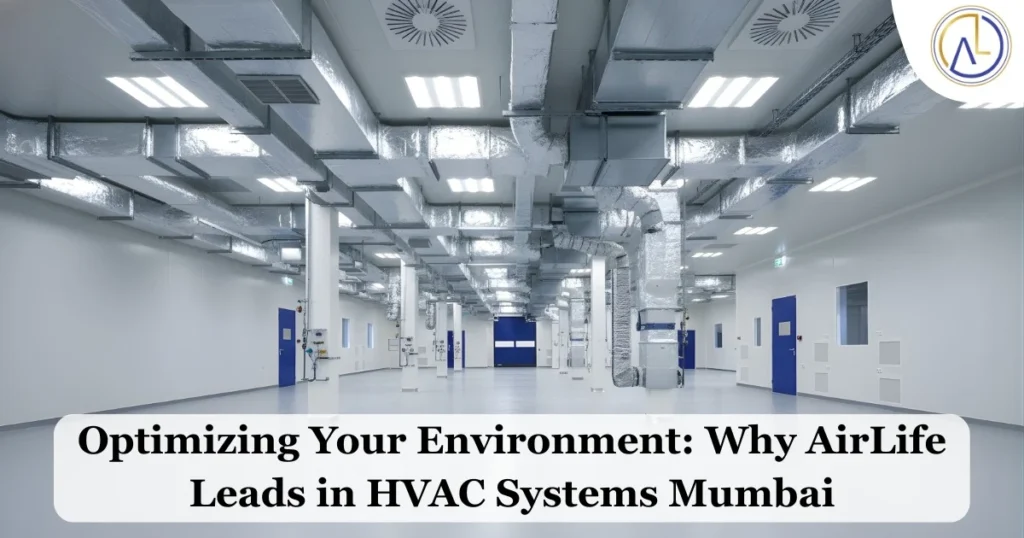

Cleanrooms are not ordinary workspaces. They are controlled environments where air quality, temperature, humidity, and pressure must remain within strict limits at all times. Even a minor lapse can affect product quality, compliance, and safety. This is exactly why AMC Services play such a crucial role in cleanroom operations.

AMC Services, or Annual Maintenance Contract Services, provide structured, planned, and professional maintenance support for cleanroom systems. Instead of reacting to breakdowns, AMC Services focus on prevention, consistency, and long-term reliability. For cleanroom-dependent industries, this approach directly translates into higher operational efficiency.

Turnkey Cleanroom Projects Explained

A turnkey cleanroom project means a single partner handles everything—design, engineering, installation, testing, and commissioning. Once the cleanroom is operational, the responsibility shifts toward maintaining that performance level throughout its lifecycle.

What Makes a Project Turnkey

Turnkey cleanrooms integrate HVAC systems, air handling units, cleanroom panels, electrical systems, automation, and validation protocols. All these systems are interconnected. If one element underperforms, the entire cleanroom environment is affected.

Integrated Systems in Cleanrooms

Because these systems are designed to work together, AMC Services must also be integrated. Fragmented maintenance often leads to inefficiencies, whereas comprehensive AMC Services maintain system harmony.

Importance of AMC Services After Project Handover

Many organizations focus heavily on cleanroom construction but underestimate post-installation maintenance. The handover stage is where AMC Services become essential.

Transition from Installation to Operation

AMC Services ensure a smooth transition from project completion to daily operations. They help retain the original design intent and performance parameters established during commissioning.

Maintaining Design Intent

Without AMC Services, systems gradually drift from their designed efficiency. Regular inspections and calibrations keep the cleanroom operating exactly as planned.

Equipment Failure and Process Interruptions

Unexpected HVAC failures, clogged HEPA filters, or electrical issues can halt production instantly. These disruptions lead to batch losses, delayed deliveries, and revenue impact.

Rising Maintenance and Energy Costs

Poorly maintained systems consume more energy and require frequent emergency repairs. AMC Services help avoid these hidden costs by keeping systems optimized.

How AMC Services Enhance Operational Efficiency

The core objective of AMC Services is efficiency—doing more with fewer interruptions.

Preventive Maintenance for Consistent Performance

Scheduled servicing, cleaning, and component checks prevent failures before they occur. This ensures stable airflow patterns, temperature control, and contamination levels.

Reduced Downtime and Improved Uptime

With AMC Services in place, downtime becomes predictable and manageable. Planned maintenance is far less disruptive than sudden breakdowns.

Data-Driven Maintenance Planning

AMC Services also involve performance tracking. Data collected during inspections helps fine-tune maintenance schedules and improve system efficiency.

Energy Optimization Through AMC Services

Energy consumption is a major operational cost in cleanrooms, especially HVAC systems.

HVAC Efficiency and Load Balancing

AMC Services help maintain optimal air changes per hour, pressure differentials, and load balancing. This prevents overworking equipment.

Cost Savings Over the Long Term

Efficient systems consume less power, extend equipment life, and reduce replacement costs—delivering long-term financial benefits.

Airlife’s Strength in Cleanroom AMC Services

Engineering brings specialized expertise in turnkey cleanroom projects and post-installation support. Their AMC Services are designed with a deep understanding of cleanroom dynamics.

- Turnkey Cleanroom Expertise

Because Airlife is involved in cleanroom engineering, their AMC Services align perfectly with system design and performance requirements.

- Skilled Service Engineers and Processes

Airlife’s trained service teams follow standardized maintenance protocols, ensuring consistency and reliability across operations.

Airlife provides comprehensive AMC Services, including:

- HVAC and AHU System Maintenance

Regular servicing to ensure airflow stability, temperature control, and humidity management.

- HEPA Filters and Airflow Validation

Integrity testing and timely replacement to maintain contamination control standards.

- Electrical Systems and Automation Support

Maintenance of panels, controls, and sensors to prevent power disruptions.

- Emergency and Breakdown Services

Quick-response AMC Services to minimize downtime during critical failures.

- AMC Services Across the Cleanroom Lifecycle

AMC Services support both immediate reliability and long-term sustainability.

- Short-Term Reliability

Frequent inspections ensure day-to-day stability and smooth operations.

- Long-Term Asset Protection

Well-maintained systems last longer, protecting the original investment in cleanroom infrastructure.

Industry-Specific Benefits of AMC Services

- Pharmaceutical and Healthcare Cleanrooms: Ensures GMP compliance and batch integrity

- Electronics and Precision Manufacturing: Maintains particle-free environments

- Food, Biotechnology, and Research Facilities: Supports hygiene and safety standards

Compliance, Documentation, and Audit Readiness

AMC Services play a critical role during audits. Proper documentation, maintenance logs, and performance records help organizations meet ISO, GMP, and regulatory requirements confidently.

Selecting the Right AMC Partner for Cleanrooms

An experienced AMC partner understands the complexity of turnkey cleanrooms. Airlife’s integrated approach ensures faster diagnostics, effective solutions, and sustained efficiency.

Conclusion

AMC Services are not just maintenance agreements—they are strategic investments in operational excellence. In turnkey cleanroom projects, AMC Services ensure consistent performance, regulatory compliance, and long-term cost efficiency. With Airlife’s specialized AMC Services, organizations can focus on production and innovation while their cleanrooms operate at peak efficiency.